Quantum Chemistry/First Principles Simulations

The thermoelectric devices depicted in Figure 1 hold great promise in increasing the efficiency of conventional power generators, renewable energy sources (solar and geothermal), and to increase the efficiency of refrigeration and air conditioning systems. Advantages of this power generation scheme include solid state operation, zero emission, vast scalability, no maintenance, long operating life, high reliability, lack of moving parts, and possibility of miniaturization. NASA has used this principle to provide electrical power for deep space probes such as Voyager I and II and the Cassini mission to Saturn.

We employ first principle simulations as a part of our multiscale approach to CNT modeling. We focus on transport properties of CNT as well as growth mechanisms. Both electrical and thermal conductivity calculated using ab initio Molecular Dynamics simulations code CPMD and Kubo-Greenwood formula. Seebeck coefficient is calculated by applying external electric potential and averaging atomic velocities at CNT termini to obtain temperature gradient along CNT. We study dependence of these properties on CNT structure and defects. Various types of defects are studied: O and N doping, C2 adatoms, chirality change (metallic/semiconducting junctions), and Bamboo structure (the presence of edge planes of graphene at regular intervals along the walls).

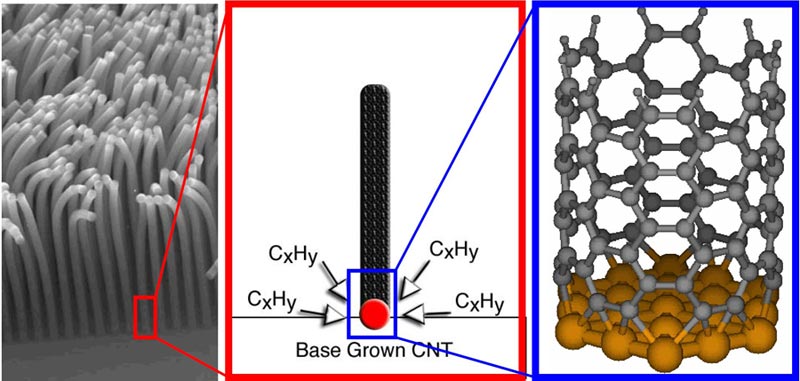

We also simulate growth of pristine and defective CNT by method of Chemical Vapor Deposition (CVD) in order to suggest venues for mass-production of designed CNT. CVD generally involves decomposition of a carbon-containing gas on a metal catalyst nanoparticle (cobalt, nickel, iron or an alloy) at temperatures above 600°C. We employ our multiscale approach combining ab intio, empirical force field, and kinetic Monte-Carlo simulations to afford simulations of carbon nanotube growth in slow regime, observed experimentally. Instead of modeling the random growth process directly, analyze detailed mechanism, identify intermediates and build kinetic model of catalytic growth. This is accomplished by global energy minimization of metal nanoclusters with CNT attached, MD simulations and trajectory analysis, combined with the search for stable intermediates of CVD process. Calculated rate constants are used in kinetic Monte Carlo simulations of the nanotube growth.

For More Information

Dr. Artëm Masunov

NanoScience Technology Center

University of Central Florida

Orlando, FL 32826